Modular Buildings

Prefabricated construction is a building process in which elements or modules of the structure are prefabricated at plants, and then transported to the construction site for installation. At the site, the modules are unloaded, moved into position with the support of heavy cranes, and assembled to form the designed building.

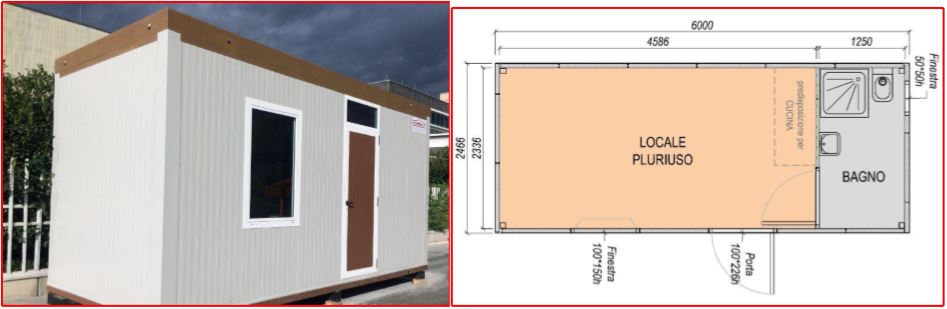

Basic Module

The basic module has a standard size of 6.00 x 2.46 ml; it is particularly versatile, it can be used singularly in the civil / productive field or, being “modular”, it allows to create aggregates of considerable surfaces, customizable and flexible according to the needs of use. The carrier is made of cold-bent steel sections, both for floor currents and for roofs; the floor and roof frames are joined with uprights in steel sections. The structures can be protected with fireproof paint up to R60 ’. The floor, equipped with thermal insulation, is made with a walking surface in panels in OSB / 3; or wood cement; the decking can be finished with a pcv mat, laminated wood, LVT slats, resin. The perimeter walls made with panels = 60mm thick consist of a double support in galvanized and pre-painted steel, insulated with rigid expanded polyurethane with high insulating power. The cover is made of 60mm thick panels made up of a double support in galvanized and pre-painted steel, insulated with rigid expanded polyurethane with high insulating power. Walls and roofs can be made with panels with mineral wool insulation according to the required fire resistance.

Modular Emergency Housing

Benefits of Pre–Fabricated / Pre–Engineered (PEB) / Modular Buildings

- Typically 40-50% less than traditional on-site construction;

- Reduced site preliminaries including hire/setup of site accommodation and other facilities;

- Building construction and site work proceed simultaneously, allowing projects to be completed in a much shorter time-span, without sacrificing safety or quality; Example: Since building of modules is done indoors rather than outdoors, bad weather does not slow down the work.

- Earlier return on investment;

- Increased predictability considering the number of projects completed on time and within budget.

- Standardised design, which is pre-approved, with a rapid and simplified procurement process;

- Innovations in technology and transportation allow for materials such as concrete, steel, and bricks to be utilized in factory built facilities;

- Design and production of Earthquake-resistant buildings;

- Standardised components allowing easier assembly with the opportunity for the exchange or addition of pre-fabricated modules;

- Efficient factory production techniques & factory-based quality control are much less wasteful and installation is less disruptive on site.

- Repetition of prefabricated units leads to considerable economy of scale in production;

- Less risk of construction equipment being stolen; replacing building materials can create price increases to clients.

- Another considerable benefit using prefabricated construction method is the energy efficiency. Because the prefab elements of a panellized home are precut, they fit snugly together, making for a tighter edifice. This means less effort for heating and cooling, resulted in lower energy bills;

- The bulk of the building construction occurs at the builder’s location, not yours, reducing many safety and scheduling concerns, and minimizing disturbances at your place of business.

- Modular construction sites have proved to be significantly safer than traditional on-site building;

- Reduction in the number of reportable accidents with consequent substantial reductions in project costs.

- The erection and finishing teams, which install and complete pre-fabricated

buildings, involve fewer workers on site than traditional buildings.

- Compared to site construction, pre-fabricated construction is about 30% of the weight of conventional masonry construction.